On a good day, a customer knows what to buy and where to buy it. They know how to get to the store and find the product they’re looking for, then go through a seamless checkout process and provide great feedback for your service. Usually, this is a process customers have generally become used to in many countries throughout the world.

Although if the supply chain is disrupted by local events, natural disasters, or global events (like a pandemic), suddenly this whole process could go up in smoke. Supply chain disruption can be extremely difficult as they reflect gaping blind spots in our supply chain framework. Often these disruptions are localized, they affect a few businesses or industries, and are quickly resolved.

The emergence of the COVID-19 global pandemic caused significant bedlam in the supply chain frameworks of businesses across the world. A study conducted by the Institute Of Supply Chain Management recorded that at least 75% of all surveyed businesses experienced a disruption in their SC due to the pandemic.

In this article, we’ll understand how our supply chains are disrupted, common causes of disruptions, and ways that you can use to create a robust supply chain management erp for the future.

Contents

What Is A Supply Chain Disruption

Supply chain disruption is a major breakdown in the production or distribution of products in a supply chain. A supply chain breakdown can occur for one or many reasons such as fire, machinery breakdown, pandemics, natural disasters, logistical issues, product issues, or an unexpected surge in capacity. This may lead to reduced productivity, increased expenditure, customer and employee dissatisfaction etc.

Supply chains lack the resilience required and are breaking down in the case of multi-country lockdowns and disruptions. Adding to this they are also becoming costlier and are have reduced sustainability.

Not all supply chain disruptions are classified as equal. Usually, all supply chain disruptions are measured based on their probability and severity. This varies based on the chain and the industry it operates in.

Here are some examples of supply chain disruptions.

Pandemics

We’ve witnessed in the last year how Covid-19 (novel coronavirus) outbreak gravely impacted global supply chains across industries. The scale and the impact of global pandemics and public health crises can be brutal on supply chains. It affects SCs, people involved, regions, and multi-national corporations at every stage of the production process.

We’ve witnessed in the last year how Covid-19 (novel coronavirus) outbreak gravely impacted global supply chains across industries. The scale and the impact of global pandemics and public health crises can be brutal on supply chains. It affects SCs, people involved, regions, and multi-national corporations at every stage of the production process.

Natural Disasters

In 2011, an earthquake struck off the Pacific coast of Japan and caused a tsunami which led to a nuclear disaster at the Fukushima Daiichi Nuclear Power Plant. This nuclear catastrophe affected all small businesses and the global economy, by halting the production of the world’s supply of 300-millimeter silicon wafers (an important component used in semiconductors) and other subsequent necessary parts. Natural disasters like tsunamis, hurricanes, wildfires, floods highlight supply chain blind spots in the overall SC framework.

In 2011, an earthquake struck off the Pacific coast of Japan and caused a tsunami which led to a nuclear disaster at the Fukushima Daiichi Nuclear Power Plant. This nuclear catastrophe affected all small businesses and the global economy, by halting the production of the world’s supply of 300-millimeter silicon wafers (an important component used in semiconductors) and other subsequent necessary parts. Natural disasters like tsunamis, hurricanes, wildfires, floods highlight supply chain blind spots in the overall SC framework.

Logistics Failures/Delays

In a globalized world, trade has made it increasingly common for businesses to include international suppliers in their supply chains. While this largely increases business opportunities it also puts weight on international and domestic transport networks leading to a choked or delayed logistical outcome. Supply chains can compound logistical problems with other uncertain variables. A natural disaster can affect the transportation of goods and services in an affected area or a country can go into lockdowns making it difficult for carriers to deliver goods by land, air, or sea even for vital products in the case of a pandemic.

In a globalized world, trade has made it increasingly common for businesses to include international suppliers in their supply chains. While this largely increases business opportunities it also puts weight on international and domestic transport networks leading to a choked or delayed logistical outcome. Supply chains can compound logistical problems with other uncertain variables. A natural disaster can affect the transportation of goods and services in an affected area or a country can go into lockdowns making it difficult for carriers to deliver goods by land, air, or sea even for vital products in the case of a pandemic.

Product Issues

Quality assurance and management is a crucial element in any supply chain management. An issue in the product can occur at any stage throughout the supply chain and so can push the business into delays of pushing out the final product. Businesses don’t want to sell mediocre goods and delay shipments due to a defective product. Hence ensuring good quality assurance in the supply chain is essential. While so many things can go wrong, let’s talk about how you can create a robust framework that improves your supply chain management.

Quality assurance and management is a crucial element in any supply chain management. An issue in the product can occur at any stage throughout the supply chain and so can push the business into delays of pushing out the final product. Businesses don’t want to sell mediocre goods and delay shipments due to a defective product. Hence ensuring good quality assurance in the supply chain is essential. While so many things can go wrong, let’s talk about how you can create a robust framework that improves your supply chain management.

How to effectively manage supply chain disruptions?

In a supply chain disruption not only businesses need to adapt to the changing circumstances but also respond to the needs of their customers, employees, suppliers, and distributors. With a robust framework, organizations reduce complexities in a disrupted supply chain and drive results. Here are 4 things to consider while developing a solid framework for managing supply chain disruptions.

- Create a response plan

- Build inventory

- Prioritize

- Configure your network

- Analyze and improve

Create A Response Plan

During any disruption, the first step is to develop an initial response plan. This will be your first plan of action. Create rules and processes for management in the disrupted situation. Establish new operations processes related to supply chain breakdowns and mobilize the command center.

During any disruption, the first step is to develop an initial response plan. This will be your first plan of action. Create rules and processes for management in the disrupted situation. Establish new operations processes related to supply chain breakdowns and mobilize the command center.

Building an inventory.

Disruptions can range from a few hours to several months or a year. In any case, you need to create buffer stockpiles of supplies that can support your business through several months of disruptions. This could mean having a warehouse full of finished goods or raw materials in case your supply chains are temporarily cut off.

Disruptions can range from a few hours to several months or a year. In any case, you need to create buffer stockpiles of supplies that can support your business through several months of disruptions. This could mean having a warehouse full of finished goods or raw materials in case your supply chains are temporarily cut off.

Continuously audit your supply chain for blindspots.

Everything has a vulnerability. You need to prioritize the risks and opportunities associated with the disruption to your SC and its components. This allows for innovation and pushes you to find effective alternatives and makes you aware of the blind spots that are potentially prone to breakdowns. We had a masterclass conversation with Jean Francois, at Ingram Micro Services on how to create an optimal technology stack for scaling eCommerce and sustaining effective supply chain management.

Everything has a vulnerability. You need to prioritize the risks and opportunities associated with the disruption to your SC and its components. This allows for innovation and pushes you to find effective alternatives and makes you aware of the blind spots that are potentially prone to breakdowns. We had a masterclass conversation with Jean Francois, at Ingram Micro Services on how to create an optimal technology stack for scaling eCommerce and sustaining effective supply chain management.

Configure your network.

While it’s recommended to have everything under one roof in case of an abrupt cut-off from the world, identify other suppliers and what they can provide to you.

While it’s recommended to have everything under one roof in case of an abrupt cut-off from the world, identify other suppliers and what they can provide to you.

By configuring and tailoring your network, all your product flows, and executive protocols you can develop a balanced supply chain and reduce delivery times.

Diversifying your supply ecosystem.

In Wall Steet, a little diversified portfolio of stocks can serve to minimize risk at scale for your investments. You can create a strong supply chain framework by:

In Wall Steet, a little diversified portfolio of stocks can serve to minimize risk at scale for your investments. You can create a strong supply chain framework by:

Developing a relationship with suppliers operating in various geographic areas.

Analyzing your shortage scenarios and working with a fulfillment expert for sourcing, planning, creating, and distributing in your production process.

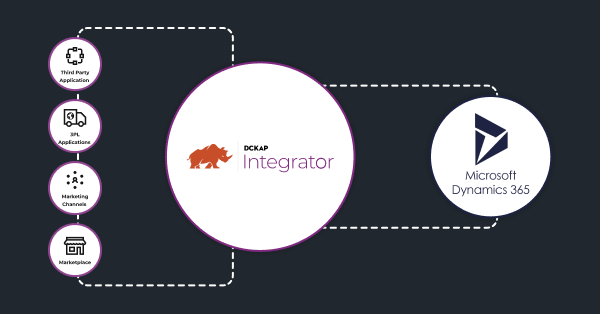

Owning a host of smart tools such as a cloud-based ERP that can be integrated with your manufacturing or distribution to provide real-time data of your business and predictive inventory analysis.

Managing any crisis, whether short-term or long-term requires a holistic approach. As an organization, your focus should be on building agile and flexible supply chain models that can pivot easily and remain resilient against future disruptions while maximizing operational capability.

This structure will be all-inclusive of emerging technologies, applied analytics, business intelligence, creativity, and innovation. It will also lend transparency across the supply chain.

But still, there’s a disruption. What now?

Planning is awesome, thinking long-term is great but unless you’re a soothsayer or can predict the future exactly you need measures to deal with failures too. Let’s take a look at some methods for efficient crisis management solutions in the event you’re in a pickle with your supply chains.

People First

Communicate with your customers, your suppliers, and your distributors. Continuously plan for your workforce safety and productivity with support and novel ways of working.

Communicate with your customers, your suppliers, and your distributors. Continuously plan for your workforce safety and productivity with support and novel ways of working.

Dive In Data

If you have data and metrics available at your disposal use them to maximize transparency across channels in your disrupted supply chain. This way you can isolate any part prone to breakdown, replace or renew it accordingly.

If you have data and metrics available at your disposal use them to maximize transparency across channels in your disrupted supply chain. This way you can isolate any part prone to breakdown, replace or renew it accordingly.

Use data to also analyze your footing in demand, existing inventory, warehouse capacity, supply, and finances across your organization.

Estimate

In the event of any disruption prioritizing decisions is key. With limited resources at your disposal ensure that you can estimate the timing of all variables which can help you return to production.

In the event of any disruption prioritizing decisions is key. With limited resources at your disposal ensure that you can estimate the timing of all variables which can help you return to production.

You also need a dedicated planning and execution team that can operate responses quickly, re-allocate resources where needed and communicate effectively. By also running simulations you can get actionable insights that will identify areas of shortage and will let you optimize resources accordingly.

Conclusion

Supply chain operations are a tricky thing owing to their interdependent nature. It’s easy to take it for granted when things are going smoothly. However, companies today have the opportunity to use this transition period to oversee their SC shortcomings and develop brand new agile and responsive chains.

These disruptions are a great way to discover areas of growth, innovation, and investments. It will push companies to evolve their supply chain structures and reposition for the eventual economic rebound.

If you liked the article, please drop a like and comment and let us know.

You can learn more about the eCommerce industry here.

Thank you for your reading this far!